To bend

metal, Press Brake machines normally use a wedge shaped upper die that

force the metal down into the V shaped lower die to bend metal to conform

with the tooling.

Click to see 4 pages of standard Press Brake Dies.

A Back Gauge can position the metal exactly where you want it, and the

Ram Depth Control is used to stop the upper die at the correct depth

down into the lower die to form the angle desired. Sophisticated tooling

can be used to form several bends simultaneously. The size of machine

required is normally determined by the thickness of the metal and width

of the bottom V-die used.

Air

Bending is when the upper die (punch) pushes the metal down into

the bottom die without bottoming the metal into the bottom die. When

the punch is raised, the metal retracts a little from the air bend position.

The amount of the retraction is the spring-back. The amount of spring

back depends on the type of metal, the thickness, grain direction and

hardness. You should expect less than a degree of spring back unless

you are bending a hard metal like stainless steel, in which case you

should use 85 degree tooling. Expect the inner bend radius to be slightly

greater than the radius of the punch. Air bending is the method normally

when calculating the tonnage required. Click for our Press

Brake Tonnage Chart to estimate the size machine you need.

Bottoming (or Coining) is when the upper die (punch) pushes the

metal all the way down into and against the bottom die. This causes

the metal to take the shape of the die set and results in very little

spring back. Coining happens if you push the metal down hard into the

bottom die. The minimum inner radius of the metal should be equal to

at least one metal thickness. Warning: Coining can easily crack brittle

metals such as aircraft aluminum. Coining requires more tonnage from

your brake press machine than does bottoming which requires more tonnage

than does air bending.

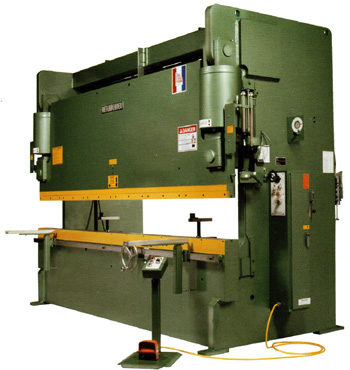

Betenbender and Chicago brand brake presses use American style tooling and come with a simple 2-Axis CNC controlled back gage and ram die depth control with memory for multiple bends to easily form your simple or complex parts jobs again and again. Complete forming jobs can be saved in memory. To program the memory you simply make your first part manually and save the ram depth and back gauge positions in the CNC memory. Whenever you make the same part again the machine knows what to do. You just have to position the metal against the back gauge. Metal forming can also be done in a manual mode for single parts.

Click if you are looking for an electric-hydraulic powered metal folding brake machine to bend your metal. They are safer, simpler, less expensive and less versatile.

PRESS BRAKE SAFETY: a Safety device such as Light Curtains are strongly recommended to prevent fingers and hands from getting crushed especially for predictable repeat uses. Safety compliance is the users responsibility. Please take it seriously. *** Click for our Machinery Safety webpage ***.

Click for chart of tensile strengths for aluminum and stainless steel to compare with mild steel. Click for a Bend Radius Chart for aluminum and stainless steel.

|

CHICAGO DREIS & KRUMP

|

|

BETENBENDER HYDRAULIC PRESS BRAKE MACHINES

|

CLICK

TO WATCH A VIDEO |

| Betenbender Press Brake Model |

Tons | Length of Bed |

Between Frame |

Open Height |

Stroke | Throat Depth |

Motor H.P. |

Weight Lbs. |

| 4-50 (4 feet x 50 tons) Click to Request a Quote |

50

|

4

feet

|

30-1/2"

|

14"

|

8"

|

8"

|

10

|

5800

|

| 6-50 (6 feet x 50 tons) Click to Request a Quote |

50

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

10

|

6800

|

| 8-50 (8 feet x 50 tons) Click to Request a Quote |

50

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

10

|

8000

|

| 10-50 (10 feet x 50 tons) Click to Request a Quote |

50

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

10

|

11000

|

| 12-50 (12 feet x 50 tons) Click to Request a Quote |

50

|

12

feet

|

126-1/2"

|

14"

|

8"

|

8"

|

10

|

12500

|

| 4-70 (4 feet x 70 tons) Click to Request a Quote |

70

|

4

feet

|

30-1/2"

|

14"

|

8"

|

8"

|

10

|

7500

|

| 6-70 Click to Request a Quote |

70

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

10

|

8000

|

| 8-70 Click to Request a Quote |

70

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

10

|

11000

|

| 10-70 Click to Request a Quote |

70

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

10

|

13000

|

| 12-70 Click to Request a Quote |

70

|

12

feet

|

126-1/2"

|

14"

|

8"

|

8"

|

10

|

14500

|

| 14-70 Click to Request a Quote |

70

|

14

feet

|

150-1/2"

|

14"

|

8"

|

8"

|

10

|

15500

|

| 6-85 Click to Request a Quote |

85

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

20

|

13000

|

| 8-85 Click to Request a Quote |

85

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

20

|

18000

|

| 10-85 Click to Request a Quote |

85

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

20

|

20100

|

| 12-85 Click to Request a Quote |

85

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

20

|

21000

|

| 14-85 Click to Request a Quote |

85

|

14

feet

|

150-1/2" |

14"

|

8"

|

8"

|

20

|

23000

|

| 6-120 Click to Request a Quote |

120

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

20

|

17000

|

| 8-120 Click to Request a Quote |

120

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

20

|

19000

|

| 10-120 Click to Request a Quote |

120

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

20

|

22000

|

| 12-120 Click to Request a Quote |

120

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

20

|

24000

|

| 14-120 Click to Request a Quote |

120

|

14

feet

|

150-1/2" |

14"

|

8"

|

8"

|

20

|

26000

|

| 6-160 Click to Request a Quote |

120

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

20

|

17000

|

| 8-160 Click to Request a Quote |

120

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

20

|

19000

|

| 10-160 Click to Request a Quote |

120

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

20

|

22000

|

| 12-160 Click to Request a Quote |

120

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

20

|

24000

|

| 14-160 Click to Request a Quote |

120

|

14

feet

|

150-1/2" |

14"

|

8"

|

8"

|

20

|

26000

|

| 6-190 Click to Request a Quote |

190

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

20

|

17000

|

| 8-190 Click to Request a Quote |

190

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

20

|

19000

|

| 10-190 Click to Request a Quote |

190

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

20

|

22000

|

| 12-190 Click to Request a Quote |

190

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

20

|

25000

|

| 14-190 Click to Request a Quote |

190

|

14

feet

|

150-1/2" |

14"

|

8"

|

8"

|

20

|

27000

|

| 6-240 Click to Request a Quote |

240

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

30

|

23000

|

| 8-240 Click to Request a Quote |

240

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

30

|

26000

|

| 10-240 Click to Request a Quote |

240

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

30

|

29000

|

| 12-240 Click to Request a Quote |

240

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

30

|

33000

|

| 6-300 Click to Request a Quote |

300

|

6

feet

|

54-1/2"

|

14"

|

8"

|

8"

|

30

|

29000

|

| 8-300 Click to Request a Quote |

300

|

8

feet

|

78-1/2"

|

14"

|

8"

|

8"

|

30

|

31000

|

| 10-300 Click to Request a Quote |

300

|

10

feet

|

102-1/2"

|

14"

|

8"

|

8"

|

30

|

33000

|

| 12-300 Click to Request a Quote |

300

|

12

feet

|

126-1/2" |

14"

|

8"

|

8"

|

30

|

35000

|

EDWARDS HYDRAULIC PRESS & BRAKE • 40

Tons capacity hydraulic shop press 220 Volts

3 phase Hydraulic Power Unit costs extra |

|

American

Machine Tools Corp.

5862

Northwest Hwy

Chicago IL 60631 USA

Phone: 773-334-5000

Fax: 773-442-0314

Click

to email us

American Machine Tools Co.

All rights reserved

Offers from American Machine Tools Corporation include include Terms and Conditions shown on our website.

Liability is strictly limited to those warranties of fitness for purpose and safety as provided by the manufacturer.

Products and Logos in this website are trademarks or registered trademarks of their respective companies or mark holders.