|

Metal

Cutting Shear

|

|||||

|

|||||

New Hydraulic Sheet Metal Shear machines

To cut sheet metal and steel plate. Also Corner notcher and edge notching machines.

A metal Shearing machine is used for cutting sheet metal to size out of a larger flat stock or from roll stock. The metal to be cut is held in place with hold-downs. 90 degree cuts are positioned by a squaring arm with scale on it or with a back gauge. Other angles are possible with an angle gauge. Large machines with shadow cut line will have a light that shines over a wire which projects a thin shadow line exactly where the cut line is which is useful if you mark your metal with a tape measure.

The shearing process can produce a shear edge burr, which can be minimized to less than 10% of the material thickness. This is a function of clearance between the blades, and the sharpness of the cutting blades. On some sheet metal shears and most plate shears, the blade gap is adjustable for different metal thicknesses. Though they are minor, the possibility of little burrs and hold down marks should be considered in the forming of some end products. Machine capacities shown for mild steel can be 33% or so higher for most types of soft aluminum, and 50% lower for stainless steel. Also, common A36 steel is usually harder than mild steel and may not cut as easy. Call an American Machine Tools sales engineer for more info. We are accredited by the Better Business Bureau with an A+ rating.

Sheet Metal Shear:

|

|

| JET Pneumatic

Air Powered Shear: Click to Request this Machine Quote Model PS-1652E with 16 gauge x 52 inch capacity This machine connects to your air compressor. 16 gauge maximum cutting capacity for mild-steel Stainless steel capacity: 18 (.048") to 20 gauge (.036") Soft aluminum and copper: 12-14 gauge (.075") 40 Strokes per Minute - Full Length 1.3 CFM Air Consumption per Stroke 25.3 CFM Air Consumption Weight: 1830 Lbs. Size: 60 x 24 x 43 Height Front Gauge Capacity (in.) 28" Back Gauge Capacity (in.) 25-1/2" Good cast-iron grade frame to eliminate blade deflection. Low cutting angle to cut narrow strips without twisting. Precise bed and beam alignment assures working accuracy. Adjustable bed for setup according to the blade clearance. Complete set of pneumatic control system. Manufactured in China. |

|

Chicago Dreis & Krump Hydraulic Sheet Metal Shear:

|

HS-414

Request a Quote |

HS-410

Request a Quote |

HS-510 |

Standard Equipment: |

|

| Capacity |

14 gauge x 52" mild steel.

20 gauge stainless |

10 gauge x 52" mild steel.

16 gauge stainless |

10 gauge x 61" mild steel.

16 gauge stainless |

|

| Back Gauge Range |

25 1/2"

Slide-Lock |

25 1/2"

Hand Cranked |

25 1/2"

Hand Cranked |

|

| Front Support Arms |

24" scales

|

34" scales

|

34" scales

|

|

| Cuts per minute |

40

|

30

|

30

|

|

| Motor HP |

3

|

5

|

5

|

|

| Shipping weight |

1610 Lbs

|

2700 Lbs

|

2900 Lbs

|

|

Air Powered Metal Shear TK1014:

Capacity: 10 feet of 14-gauge mild steel |

|

Hydraulic Sheet Metal Shear Machines: normally in stock

10 gauge x 10 feet: Request

this Quote |

|

Chicago brand Hydraulic Metal Plate Cutting Shears: EHS |

|

| CLICK

TO SEE A VIDEO • CLICK

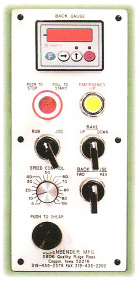

TO SEE ANOTHER VIDEO EHS Models: 24" back gauge • 42" squaring and support arms • Back gauge readout accurate to .005" • Control panel directly on machine • Selected blade gap choices • Nitrogen ram return • Steel frame. |

|

Capacity

(inches) |

Capacity

(mm) |

SPM

|

N.C.

Back Gauge |

Front

gauge |

Motor

H.P. |

Weight

(Lbs) |

|

EHS 1540

Request this Quote |

3/16"

x 63"

|

4.5

x 1600

|

22

|

24"

|

42"

|

7.5

|

6600

|

|

EHS 2540

Request this Quote |

3/16"

x 98"

|

4.5

x 2500

|

22

|

24"

|

42"

|

7.5

|

9250

|

|

EHS 3132

Request this Quote |

10

gauge x 122"

|

13

x 2500

|

24

|

31.5"

option |

49"

|

7.5

|

8500

|

|

EHS 3140

Request this Quote |

3/16"

x 122"

|

4.5

x 3100

|

18

|

24"

|

42"

|

7.5

|

10550

|

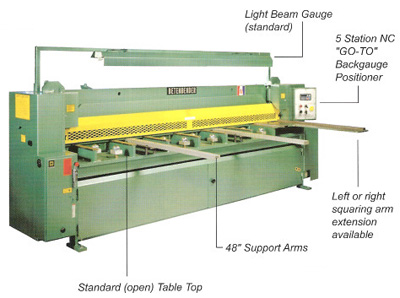

Betenbender Hydraulic Metal Shear Machines: made in USA.* Sizes 1/8" to 3/4" thick * 36" Power Backgauge with LED Readout * Inch / Metric. * 4 foot Squaring Arm with Inlaid Scale * All Hydraulic Fluids Included * All Steel Construction * American Made Motor, Valves, Hoses and Fittings * Hour Meter * Hydraulic Pressure: 2500 psi * Hydraulic Self-Compensating * Holddown Bar Assembly * Light Beam Gauge (Shadow Line) * Linemaster Foot Switch * Manual Rapid Blade Gap Adjustment (3/8" and Larger) * Manual Swing-up Backgauge * NEMA Electrics * Power Adjust Variable Rake Angle * Safety Switch for Front Guard * Single Piece Top and Bottom, Shock Resistant Knives with Four Cutting Edges

4-125: 4 feet x 1/8"

Click to Request this Quote

4-25: 4 feet x 1/4"

Click to Request this Quote

4-375: 4 feet x 3/8"

Click to Request this Quote

4-500: 4 feet x 1/2"

Click to Request this Quote

4-750: 4 feet x 3/4"

Click to Request this Quote |

|

Hydraulic 90 degree Corner Notcher: |

|||

|

* Dual head design * Centralized control panel * Foot switch * Sheet supports * Material hold downs * Modes of Operation; single / inch / continuous * Fine scale adjustment * Slug chute * Dual gauge systems |

||

|

Model

Number |

Capacity

|

Max.

Square Notch |

Edge

Notch (X x Y) |

Ram

Stroke |

SPM

|

Motor

HP |

|

|

Mild Steel

|

Stainless

|

||||||

| HN-10 Request Quote |

10 gauge

(.135") |

16 gauge

(.06) |

8-5/8"x 8-5/8"

|

4" x 2"

|

1"

|

22

|

2

|

| HN-25 Request Quote |

1/4"

|

10 gauge

(.135") |

10" x 10"

|

6" x 4"

|

1-1/2"

|

20

|

5

|

|

Lever operated Sheet Metal Corner Notcher Available

from Jet or Tin Knocker |

|

Click for American Machine Tools Homepage

American

Machine Tools Co.

5862

Northwest Hwy

Chicago IL 60631 USA

Phone: 773-334-5000

Fax: 773-442-0314

Click

to email us

American Machine Tools Co.

All rights reserved

Offers from American Machine Tools Corporation include Terms and Conditions shown on our website.

Liability is strictly limited to those warranties of fitness for purpose and safety as provided by the manufacturer.

Products and Logos in this website are trademarks or registered trademarks of their respective companies or mark holders.