|

PLATE

ROLLS

|

|||||

A+ Rating

A+ Rating

For rolling sheet metal and plate into semi-circles, cylinder shapes or cones.

Tell us what size and type of metal you need to form and the radius to be formed. You will like our price.

Scroll down below to see photos and specifications of many different machines.

Interested

in curving your sheet metal or plate? We have 3 roll and 4 roll benders

that work by pinching the metal between the top and bottom rolls and

curving it as it comes in contact with a back forming roll. This curves

the metal workpiece into a cylindrical form, where it is welded together

to produce a cylinder. The support end of the top shaft can be opened

to allow removal of the finished work piece, especially a completed

tube shape. You may also weld the seam while its still on the machine

(ground to part with machine power off).

Note: Without alot of skill, on 3 roll machines, it can be very difficult

to form metal into cylindrical shapes smaller than 3 times the upper

roll diameter when forming near capacity thickness. 1.5 times the upper

roll diameter is often the tightest diameter using thinner and narrower

metal. Results vary depending on metal thickness, width, tensile strength

and on your level of expertise.

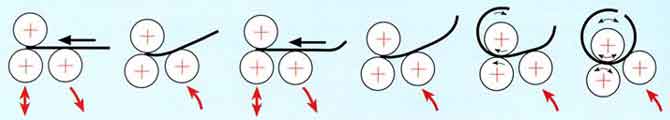

Below

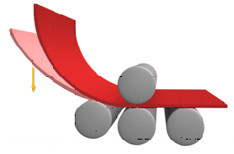

is a diagram showing how a plate is formed into a tube with a single (initial)

pinch plate rolling machine.

Single-pinch (initial-pinch) machines are the most common and may require inserting the workpiece into the machine twice in order to prebend both ends to eliminate flat spots when rolling a full tube shape and to ensure better closure of the seam. To prebend the first end, the operator inserts the plate into the machine, which clamps it and pinches it between the top roll and bottom pinch roll. A rear bending roll, moving diagonally toward the top roll, pushes against the metal to bend the radius. The operator then removes the plate from the bender, rotates the plate 180 degrees to insert the second end into the rolls, then rolls the cylinder to completion. Recommended maximum thickness (or width instead) for prebending is usually 3/4 of the capacity of the machine. Bending thickness can be increased slightly if rolling a narrower width. Consult American Machine Tools Company for advice.

Double pinch pyramid machines with 3 rolls can prebend both ends of a plate with a single insertion into the bending machine, for reduction in material handling and time. But they cost more and cannot roll as tight a diameter. The wide opening between the rolls allows heavy plate to be rolled. On double pinch machines, the top roll position is fixed and the two lower rolls move in a straight path or an arc toward the top roll. The downside is that after prebending the leading edge, control of the plate needs to be passed over to the other bottom roll which switches rolls from bending roll to pinch roll.

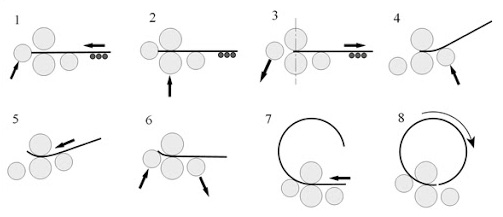

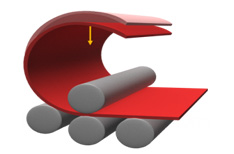

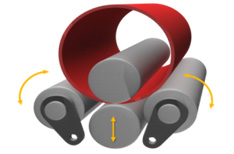

Finally, 4 roll machines can accurately roll metal to tight diameters and can do it in one pass through because the metal is always held in position by the bottm pinch roll while the 3rd and 4th rolls take turns curving the metal. You can make cylinder shapes, oval shapes, cone shapes, semi-curves, and shapes with curves and straight sections. We sell Akyapak four roll machines. Scroll way down to see them. Below is a diagram of how to roll a plate into a cylindrical shape on a 4 roll machine.

Forming a full tube shape should have little or no gap in the middle of the seam due to the "crowning" of the rolls. Crowning is where the rolls are slightly larger diameter in the middle which compensates for deflection under load. If the crowning is not enough try wrapping and taping a piece of shim stock around the middle of the bending roll to over-compensate for deflection. Crowning has a side effect of causing very thin metal to have a gap at the ends. If a gap occurs, either in the middle or the ends, it can be pulled together using a ratchet strap, come-along, clamps or the vise grips with chain attachment. If you want to roll thick flat bar, pipe, tubing, angle iron or channel into a curve then go to Pipe and Structural Shape Bending angle roll machines.

On most of our machines, rolling a sheet metal cone shape can be formed by pre-cutting a flat metal blank with the correct inner and outer radius to form the cone (funnel) shape wanted. Normally the blank is fed on one side so that the inner radius can be slowed or stopped against a cone rolling attachment. The inner radius is supposed to go thru the rolls slower than the outer radius. The bending (forming) roll position should be independently adjusted lower on on the drive side to help taper the cone. Cones take a lot of time to make. Fabricators usually practice with cardboard and then scrap metal first. The maximum cone size is about half the length of the rolls. Contact an American Machine Tools sales engineer for more information.

WARNING:

Powered roll machines are very dangerous if used carelessly because they

can crush fingers, hands, etc. Always keep hands, fingers, hair and clothing

clear. Safety guarding or devices such as Light Curtains are recommended

for predictable repeat uses. Safety compliance is the users responsibility.

You must take it seriously.

*** Click for our Machinery Safety webpage

***.

Capacity

increases with soft aluminum and decreases 33% with stainless steel.

Click for chart of tensile strengths for aluminum and stainless steel

(to calculate equivalent machine capacity)

|

26

gauge

|

24

ga.

|

22

ga.

|

20

ga .

|

18

ga.

|

16

ga.

|

14

ga.

|

13

ga.

|

12

ga.

|

11

ga.

|

10

ga.

|

9

ga.

|

8

ga.

|

7

ga.

|

6

gauge

|

|

.018"

|

.024"

|

.030"

|

.036"

|

.048"

|

.060"

|

.075"

|

.090"

|

.105"

|

.120"

|

.135"

|

.150"

|

.164"

|

.180"

|

.194"

|

|

.46mm

|

.61mm

|

.76mm

|

.91mm

|

1.2mm

|

1.5mm

|

1.9mm

|

2.3mm

|

2.7mm

|

3mm

|

3.4mm

|

3.8mm

|

4mm

|

4.6mm

|

4.9mm

|

Thickness Conversion Chart for Steel Sheet Metal: Gauge to thickness in inches and metric

|

Chicago Dreis & Krump SR-2420:

$1175. SR-3622:

$1350. SR-5016:

$3750. includes the stand |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

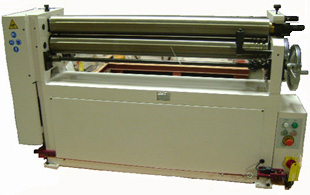

Electric Powered Slip Rolls:* Rolls are

turned, ground, and polished high grade steel. |

Birmingham shown above, JET is shown below |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GMC SINGLE

PINCH BENDING ROLLS:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Machine |

Capacity

|

Dia of

Rolls |

Choose machine to request a quote for |

| PBR0412 |

48"

x 12 gauge

|

3.5"

|

Click to request this Quote |

| PBR0418 |

48"

x 7 gauge

|

4.75"

|

Click to request this Quote |

| PBR0425 |

48"

x 1/4

|

5.75"

|

Click to request this Quote |

| PBR0510 |

60"

X 10 gauge

|

4.75"

|

Click to request this Quote |

| PBR0610 |

80"

x 10 gauge

|

5"

|

Click to request this Quote |

| PBR0810 |

98"

x 10 gauge

|

6"

|

Click to request this Quote |

| PBR1010 |

120"

x 10 gauge

|

6.7"

|

Click to request this Quote |

Photo shows how top roll swings open |

Photo shows cone former and 3 grooves |

Photo shows optional Digital Readout |

All 3 rolls are driven by a hydraulic motor. Crowned alloy steel rolls. Foot control for forward and reverse. Bending roll is hydraulically powered up and down with digital readout showing position. Bending roll cylinders adjust in synch or independently to help for making cones. Grooves at one end for rolling round bar sizes 3/8", 1/2", 5/8". Cone forming attachment is included. Good medium use machine made in Taiwan. Almost always in stock.

Click to see a nice VIDEO of this Bending Roll

|

Machine

|

Capacity

|

Diameter

of Rolls |

Click below to request

a quote for a machine

|

|

HBR-0425

|

1/4"

x 4 feet

|

6"

|

|

|

HBR-0525

|

1/4"

x 5 feet

|

7"

|

|

|

HBR-0625

|

1/4"

x 6 feet

|

7.5"

|

|

|

HBR-0808

|

8

gauge x 8 ft

|

6.5"

|

BIRMINGHAM

3-ROLL SINGLE-PINCH HYDRAULIC PLATE BENDING ROLLS:

All

3 rolls driven hydraulically. Crowned alloy steel rolls. Foot control

(not shown) with forward and reverse. Bending roll is hydraulically

powered up and down with digital readout showing position. Bending

roll cylinders adjust in synch or independently to help if making

cones. Optional custom made attachment helps forming of cone shapes.

Good medium use machine made in Taiwan.

Click to see a VIDEO of this Bending Roll

| Machine |

Capacity

|

Diameter

of Rolls |

Click below to request a quote for a machine |

| R-0440H |

51"

X 8 gauge

|

4.75"

|

Click for this Quote |

| R-0535H |

61"

x 10 gauge

|

4.75"

|

Click for this Quote |

| R-0625H |

80"

x 12 gauge

|

4.75"

|

Click for this Quote |

| R-0465H |

51"

X 1/4

|

5.87"

|

Click for this Quote |

| R-0545H |

61"

x 3/16

|

5.87"

|

Click for this Quote |

| R-0640H |

80"

x 8 gauge

|

5.87"

|

Click for this Quote |

| R-0480H |

51"

X 5/16"

|

7"

|

Click for this Quote |

| R-0570H |

61"

x 9/32"(.28)

|

7"

|

Click for this Quote |

| R-0650H |

80"

x 6 gauge

|

7"

|

Click for this Quote |

| R-0830H |

100"

x 1/8

|

8"

|

Click for this Quote |

| R-0845H |

100"

x 3/16"

|

8"

|

Click for this Quote |

|

1. Electrical

control cabinet. |

1. Photo

shows top roll being swiveled out (for removing a completely

formed tube). |

|

CHICAGO

DREIS & KRUMP

|

*

Hydraulic powered bending roll adjustment.

* Push button GO-TO Positioning of bending roll with Digital Readout

for easy repeat parts.

* Push button Hydraulic powered pinch roll adjustment.

* Push button Hydraulic powered opening of top roll for finished

part removal.

* Hydraulic powered tilting of bending roll.

* Forged steel rolls hardened to RC45.

* Cone forming attachment included.

* Push button pendant control.

* Spherical roller bearings on all 3 roll shafts.

* Heavy duty reinforced welded steel frame.

* Emergency stop cable around the machine.

* Keyed main on-off switch.

* Good machine for frequent use.

| Machine | Capacity |

Dia. of Rolls

|

Click below to request a quote for a machine |

| IPR 4075 | 14 gauge x 50" |

3.1"

|

Click for Quote |

| IPR 4120 | 11 gauge x 50" |

3.9"

|

Click for Quote |

| IPR 4160 | 9 gauge x 50" |

4.7"

|

Click for Quote |

| IPR 4250 | 1/4 x 50" |

6.3"

|

Click for Quote |

| IPR 4375 | 3/8 x 50" |

7"

|

Click for Quote |

| IPR 4560 | 9/16 x 50" |

7.9"

|

Click for Quote |

| IPR 5060 | 16 gauge x 61" |

3.1"

|

Click for Quote |

| IPR 5090 | 13 gauge x 61" |

3.9"

|

Click for Quote |

| IPR 5125 | 1/8 x 61" |

4.7"

|

Click for Quote |

| IPR 5250 | 1/4 x 61" |

6.3"

|

Click for Quote |

| IPR 5312 | 5/16 x 61" |

7"

|

Click for Quote |

| IPR 6075 | 14 gauge x 72" |

4.7"

|

Click for Quote |

| IPR 6187 | 3/16 x 72" |

6.3"

|

Click for Quote |

| IPR 6250 | 1/4 x 72" |

7"

|

Click for Quote |

| IPR 8125 | 1/8 x 96" |

6.3"

|

Click for Quote |

| IPR 8187 | 3/16 x 96" |

7"

|

Click for Quote |

| IPR10160 | 9 gauge x 120" |

7"

|

Click for Quote |

All push button operation instead of foot pedal and handwheel. The lower pinch roll has our special hydraulic powered "quick gap set" which is a real time saver for metal thickness set up. The pinch roll is also easily tiltable for cone rolling. An adjustable position attachment for making cones is included. It allows for both the stop-start-adjust method or the vice grip holding method of cone rolling. Push button hydraulic opening of the top roll bearing assembly for easy finished part removal. As with all CHICAGO bending rolls, the frames are made of extra heavy welded steel construction. The rolls are made from forged steel and heat treated to RC45. Heavy duty spherical roller bearings on all three rolls minimize friction loss. The rear bending roll is equipped with a GO TO LED digital readout indicating its position for accurate repeat forming. Positioning of the rear bending roll is done hydraulically via push buttons and allows the operator to tilt it for cone forming. An emergency stop button and keylock on/off power switch are centrally located on the control panel. Excellent machine for frequent use.

|

|

BIRMINGHAM 3-ROLL DOUBLE-PINCH HYDRAULIC PLATE BENDING ROLL MACHINE:

| Machine | Capacity |

Dia. of Rolls

|

Click below to request a quote for a machine |

| RH-0506 | 61" x 1/4 |

8"

|

Click for Quote |

| RH-0606 | 80" x 1/4 |

8"

|

Click for Quote |

| RH-0805 | 100" x 6 gauge |

8"

|

Click for Quote |

| RH-1004 |

120"

x 3/16

|

8"

|

Click for Quote |

| RH-0508 | 61" x 5/16" |

9"

|

Click for Quote |

| RH-0608 | 80" x 5/16" |

9"

|

Click for Quote |

| RH-0806 | 100" x 1/4" |

9"

|

Click for Quote |

| RH-1005 | 120" x 6 gauge |

9"

|

Click for Quote |

| RH-0510 | 61" x 3/8" |

10"

|

Click for Quote |

| RH-0610 | 80" x 3/8" |

10"

|

Click for Quote |

| RH-0808 | 100" x 5/16" |

10"

|

Click for Quote |

| RH-1006 | 120" x 1/4" |

10"

|

Click for Quote |

| RH-0613 | 80" x 1/2" |

11"

|

Click for Quote |

| RH-0810 | 100" x 3/8" |

11"

|

Click for Quote |

| RH-1008 | 120" x 5/16" |

11"

|

Click for Quote |

| RH-0616 | 80" x 5/8" |

12.25"

|

Click for Quote |

| RH-0813 | 100" x 1/2" |

12.25"

|

Click for Quote |

| RH-1010 | 120" x 3/8" |

12.25"

|

Click for Quote |

* Push button

control panel (not shown in photo above)

* All 3 rolls hydraulically driven independently.

* Digital Readouts of 2 lower roll positions.

* Hardened and ground alloy steel rolls.

* Rolls have pressure compensating camber.

* Sealed spherical roller bearings.

* Hydraulic powered bending roll adjustment.

* Digital Readout Positioning of bending roll.

* Push button Hydraulic powered pinch roll adjustment.

* Push button Hydraulic powered opening of top roll for finished

part removal.

* Spherical roller bearings on all 3 roll shafts.

* Heavy duty reinforced welded steel frame.

* Emergency stop cable around the machine.

* Optional Cone Bending attachment available.

* Optional Infinitely variable rolling speeds available

CLICK

TO WATCH A SHORT VIDEO

CLICK

TO WATCH A LONG VIDEO

|

|

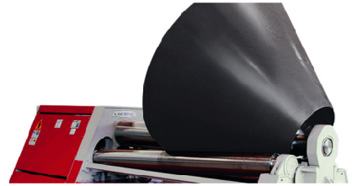

AKYAPAK AHS 4-Roll Plate Roll Machines

View our huge selection of Akyapak AHS 4 Roll Plate Rolls. Please find the size you are interested in below based on the length and pre-bend thickness then click the model number to request a quote. We will send you a formal quotation with prices and complete information within 72 hours.

The Akyapak Company manufactures 4 rolls hydraulic plate bending machines with capacity in thickness from from 14 gauge to 6 inches thick and widths from 20 inches to 40 feet (2 mm to 150 mm and in width from 500 mm to 12000 mm)

Productive and Reliable

As well as being reliable, AHS increases productivity with its high speed rolling ability and it overcomes the most challenging bends thanks to its ease of use. Since the plate is pinched during rolling, unwanted skidding and slipping of your material is prevented.

In AHS 4-Roll Plate Rolling Machines, one of the side rolls can be used as a squaring roll, thus the plate can be easily and precisely aligned along the roll across the input direction.

Less Flat Ends with a Single Pass

On AHS 4-Roll Machines, it is possible to achieve a full cylinder in a single pass because the metal can be pinched with the lower-roll during pre-bending and bending. AHS model allows for precise pinching of the plate between upper and lower rolls.

STANDARD

EQUIPMENT:

*

Cone bending device

* Induction

hardened rolls

* Digital

display for side rolls

* Fully

welded steel (St-52) construction body

* Separate

movable control panel

* Two

rolling speeds

* Electro-hydraulic

calibration

* All

rolls are mounted in roller spherical roller bearings

* Safety

equipment around the machine

* Central

rolls are driven by hydraulic motors and planetary gearboxes

* Certified

by CE, ISO9001 – 2008, TSEK and TURQUM

OPTIONS

AVAILABLE:

* Central

Overhead Support to prevent sagging of huge diameters

* Side

Supports to control large diameters

* Variable

Speed of rotation

* Material

feeding table to easy loading

* Interchangeable

top roll

* Oil

cooling system

* Driven

side rolls to roll a tighter diameter

* Deflection

compensating system

* Motors

in variable voltage and frequency

* Automatic

material ejection equipment

* Automatic

loading and unloading system

* NC

Control System for easy repeat work

* CNC

Control System for production work

MANY SIZES IN STOCK! CALL 1-773-334-5000 or Click MODEL NUMBER To Request a Quote

|

Click

the Model to Request a Price

|

Working

Length (feet)

|

Maximum

Thickness (inches)

|

Pre-Bend

Thickness

(inches) |

Top

Roll Diameter (inches)

|

Bottom

Roll Diameter (inches)

|

Side

Roll Diameter (inches)

|

Motor

Power

(HP) |

Weight

(Lbs.) |

|

4

|

1/4

|

8

ga.

|

4.7

|

4.7

|

3.9

|

2

|

4000

|

|

|

5

|

1/4

|

8

ga.

|

5.5

|

5.5

|

4.7

|

3

|

4409

|

|

|

5

|

9/32

|

6

ga.

|

6.3

|

5.5

|

4.7

|

3

|

4630

|

|

|

5

|

3/8

|

5/16

|

7.5

|

6.7

|

5.9

|

4

|

4453

|

|

|

5

|

1/2

|

3/8

|

8.3

|

7.5

|

6.7

|

4

|

4800

|

|

|

6

|

8

ga.

|

14

ga.

|

5.5

|

5.5

|

4.7

|

3

|

4938

|

|

|

6

|

1/4

|

8

ga.

|

6.3

|

5.5

|

4.7

|

3

|

5181

|

|

|

6

|

5/16

|

1/4

|

7.5

|

6.7

|

5.9

|

4

|

7606

|

|

|

6

|

3/8

|

5/16

|

8.3

|

7.5

|

6.7

|

10

|

9700

|

|

|

6

|

1/2

|

3/8

|

9.1

|

8.3

|

7.5

|

10

|

10472

|

|

|

6

|

5/8

|

1/2

|

10.6

|

9.8

|

8.3

|

15

|

12897

|

|

|

6

|

13/16

|

5/8

|

11.8

|

10.6

|

8.3

|

20

|

15212

|

|

|

6

|

1

|

13/16

|

13.0

|

11.8

|

9.4

|

20

|

20106

|

|

|

6

|

1-3/16

|

1

|

14.2

|

13.0

|

9.8

|

25

|

25906

|

|

|

6

|

1-9/16

|

1-3/16

|

15.4

|

14.2

|

11.8

|

30

|

37920

|

|

|

6

|

1-3/4

|

1-3/8

|

16.9

|

15.4

|

13.0

|

40

|

54564

|

|

|

6

|

2

|

1-9/16

|

18.1

|

16.5

|

14.2

|

50

|

55116

|

|

|

8

|

1/4

|

8

ga.

|

7.5

|

6.7

|

5.9

|

4

|

7937

|

|

|

8

|

5/16

|

1/4

|

8.3

|

7.5

|

6.7

|

10

|

10582

|

|

|

8

|

3/8

|

5/16

|

9.1

|

8.3

|

7.5

|

10

|

11773

|

|

|

8

|

1/2

|

3/8

|

10.6

|

9.8

|

8.3

|

15

|

14991

|

|

|

8

|

5/8

|

1/2

|

11.8

|

10.6

|

8.3

|

15

|

17857

|

|

|

8

|

13/16

|

5/8

|

13.0

|

11.8

|

9.4

|

20

|

20944

|

|

|

8

|

1

|

13/16

|

14.2

|

13.0

|

9.8

|

25

|

26015

|

|

|

8

|

1-3/16

|

1

|

15.4

|

14.2

|

11.8

|

30

|

34833

|

|

|

8

|

1-9/16

|

1-3/16

|

16.9

|

15.4

|

13.0

|

40

|

49163

|

|

|

8

|

1-3/4

|

1-3/8

|

18.1

|

16.5

|

14.2

|

40

|

62832

|

|

|

8

|

2

|

1-9/16

|

20.1

|

18.1

|

15.4

|

60

|

67682

|

|

|

8

|

2-3/8

|

2

|

21.3

|

20.1

|

17.3

|

74

|

88185

|

|

|

10

|

1/4

|

8

ga.

|

8.3

|

7.5

|

6.7

|

10

|

11905

|

|

|

10

|

5/16

|

1/4

|

9.1

|

8.3

|

7.5

|

10

|

12853

|

|

|

10

|

3/8

|

5/16

|

10.6

|

9.8

|

8.3

|

15

|

17086

|

|

|

10

|

1/2

|

3/8

|

11.8

|

10.6

|

8.3

|

15

|

19401

|

|

|

10

|

5/8

|

1/2

|

13.0

|

11.8

|

9.4

|

15

|

23369

|

|

|

10

|

13/16

|

5/8

|

14.2

|

13.0

|

9.8

|

20

|

26632

|

|

|

10

|

1

|

13/16

|

15.4

|

14.2

|

11.8

|

25

|

37699

|

|

|

10

|

1-3/8

|

1-1/8

|

16.9

|

15.4

|

13.0

|

30

|

49780

|

|

|

10

|

1-3/8

|

1-3/16

|

18.1

|

16.1

|

13.4

|

30

|

66690

|

|

|

10

|

1-9/16

|

1-1/4

|

18.1

|

16.5

|

14.2

|

40

|

66756

|

|

|

10

|

1-3/4

|

1-3/8

|

18.9

|

17.3

|

15.0

|

40

|

69446

|

|

|

10

|

1-3/4

|

1-3/8

|

20.1

|

18.1

|

15.4

|

60

|

73855

|

|

|

10

|

2

|

1-9/16

|

21.3

|

20.1

|

17.3

|

74

|

88185

|

|

|

13

ft. 3"

|

1/4

|

8

ga.

|

10.6

|

9.8

|

8.3

|

10

|

19621

|

|

|

13

ft. 3"

|

5/16

|

1/4

|

11.8

|

10.6

|

8.3

|

10

|

21892

|

|

|

13

ft. 3"

|

3/8

|

5/16

|

13.0

|

11.8

|

9.4

|

10

|

32893

|

|

|

13

ft. 3"

|

1/2

|

3/8

|

14.2

|

13.0

|

9.8

|

14.8

|

35274

|

|

|

13

ft. 3"

|

5/8

|

1/2

|

15.4

|

14.2

|

11.8

|

20

|

44313

|

|

|

13

ft. 3"

|

13/16

|

5/8

|

16.9

|

15.4

|

13.0

|

24.8

|

53352

|

|

|

13

ft. 3"

|

1

|

13/16

|

18.1

|

16.5

|

14.2

|

29.5

|

75839

|

|

|

13

ft. 3"

|

1-3/16

|

1

|

20.1

|

18.1

|

15.4

|

40.2

|

85098

|

|

|

13

ft. 3"

|

1-3/8

|

1-1/8

|

21.3

|

20.1

|

17.3

|

49.6

|

106042

|

|

|

13

ft. 3"

|

1-9/16

|

1-1/4

|

22.8

|

21.3

|

18.1

|

60.3

|

113318

|

|

|

13

ft. 3"

|

2

|

1-9/16

|

24.8

|

23.6

|

21.7

|

60.3

|

141537

|

|

|

16

ft. 6"

|

3/8

|

5/16

|

14.2

|

13.0

|

9.8

|

14.8

|

49604

|

|

|

16

ft. 6"

|

1/2

|

3/8

|

15.4

|

14.2

|

11.8

|

14.8

|

50045

|

|

|

16

ft. 6"

|

5/8

|

1/2

|

16.5

|

15.4

|

13.0

|

20

|

65036

|

|

|

16

ft. 6"

|

13/16

|

5/8

|

18.1

|

16.5

|

14.2

|

24.8

|

86421

|

|

|

16

ft. 6"

|

1

|

13/16

|

20.1

|

18.1

|

15.4

|

40.2

|

95901

|

|

|

16

ft. 6"

|

1-3/16

|

1

|

22.0

|

20.5

|

17.3

|

49.6

|

118609

|

|

|

16

ft. 6"

|

1-3/4

|

1-7/16

|

24.8

|

23.6

|

20.5

|

60.3

|

159174

|

|

|

16

ft. 6"

|

2-3/16

|

1-3/4

|

28.3

|

26.8

|

23.6

|

73.8

|

197755

|

|

|

20

|

5/16

|

1/4

|

14.2

|

13.0

|

9.8

|

14.8

|

47620

|

|

|

20

|

3/8

|

5/16

|

15.4

|

14.2

|

11.8

|

14.8

|

55667

|

|

|

20

|

1/2

|

3/8

|

16.9

|

15.4

|

13.0

|

20

|

72.753

|

|

|

20

|

5/8

|

1/2

|

18.1

|

16.5

|

14.2

|

24.8

|

95901

|

|

|

20

|

13/16

|

5/8

|

20.1

|

18.1

|

15.4

|

40.2

|

106924

|

|

|

20

|

1

|

13/16

|

22.0

|

20.5

|

17.3

|

49.6

|

132939

|

|

|

20

|

1-9/16

|

1-1/8

|

25.6

|

24.0

|

20.5

|

73.8

|

163583

|

|

|

20

|

2

|

1-7/16

|

29.5

|

27.6

|

22.8

|

100

|

216000

|

Click for the American Machine Tool Homepage

5862 Northwest Hwy

Chicago IL 60631 USA

Phone: 773-334-5000

Fax: 773-442-0314

Click to email us

American Machine Tools Co.

All rights reserved

Offers from American Machine Tools Corporation include include Terms and Conditions shown on our website.

Liability is strictly limited to those warranties of fitness for purpose and safety as provided by the manufacturer.

Products and Logos in this website are trademarks or registered trademarks of their respective companies or mark holders.